| Availability: | |

|---|---|

| Quantity: | |

carbide rods

Jinxin

Product Description

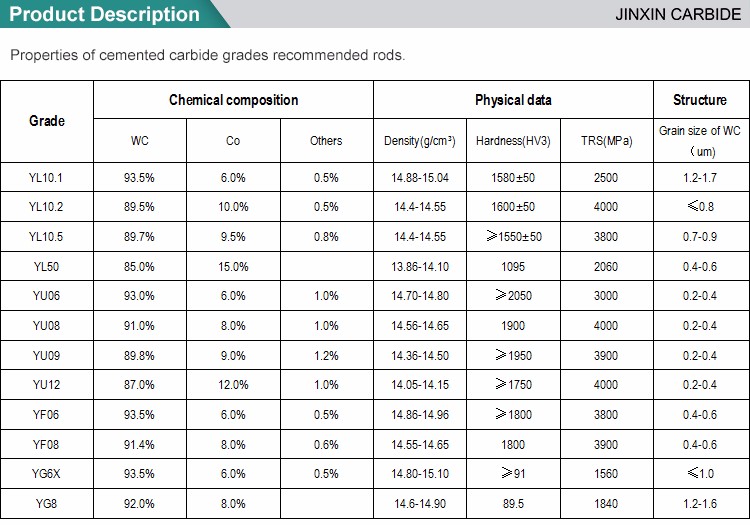

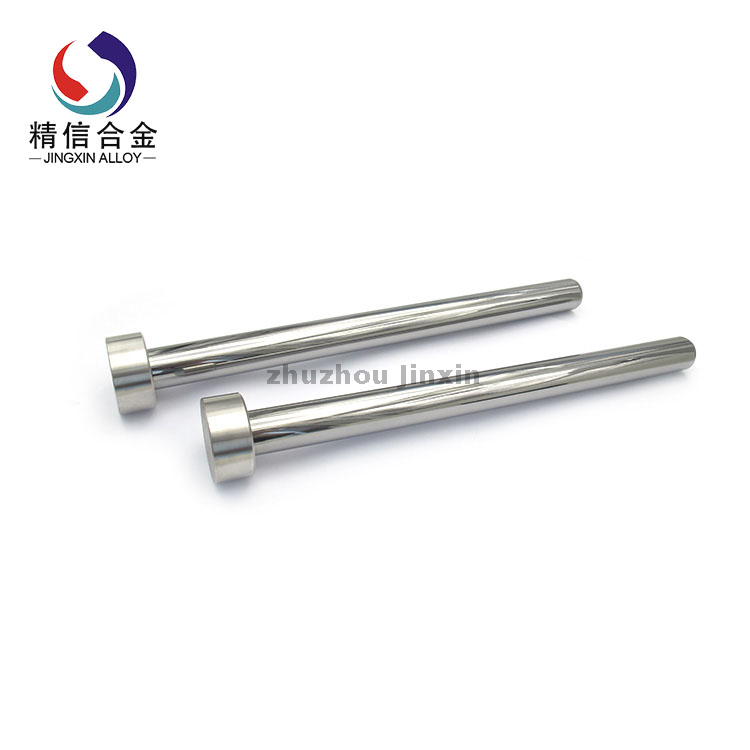

Mirror surface tungsten carbide rods plunger is a high-performance cemented carbide product made of tungsten carbide (WC) and cobalt (Co) and other metal powders by pressing, sintering and other processes. Its surface is specially treated to achieve mirror effect, with extremely high hardness, wear resistance, corrosion resistance and good chemical stability. This kind of plunger is widely used in high-pressure pumps, hydraulic equipment, oil drilling, mining machinery and other fields, as a key component to withstand high pressure, high speed, high wear conditions.

1.Main Features

High hardness: the tungsten carbide alloy has extremely high hardness, which usually reaches HRA 90 or above, and can effectively resist the abrasion of various hard objects.

Wear resistance: due to its high hardness and good wear resistance, mirror surface tungsten carbide alloy bar plunger can still maintain good dimensional accuracy and surface finish in long time use.

Corrosion resistance: tungsten carbide alloy has good stability to many kinds of chemical substances and is not easy to be corroded.

Mirror effect: The surface is specially treated to achieve mirror effect, which reduces the friction resistance and improves the sealing and service life.

High Precision: Strict control of dimensional accuracy and shape accuracy during the production process ensures that the product meets the design requirements.

2.Areas of application

High-pressure pumps: as the plunger part of high-pressure pumps, it withstands high pressure and high-speed impact.

Hydraulic equipment: as a key component in the hydraulic system, transmitting pressure and power.

Oil drilling: used in oil drilling equipment, such as drill bits, drill rods and other components, to withstand high wear and harsh working conditions.

Mining Machinery: used as parts of crushing and grinding equipment in mining machinery to improve the wear resistance and service life of the equipment.

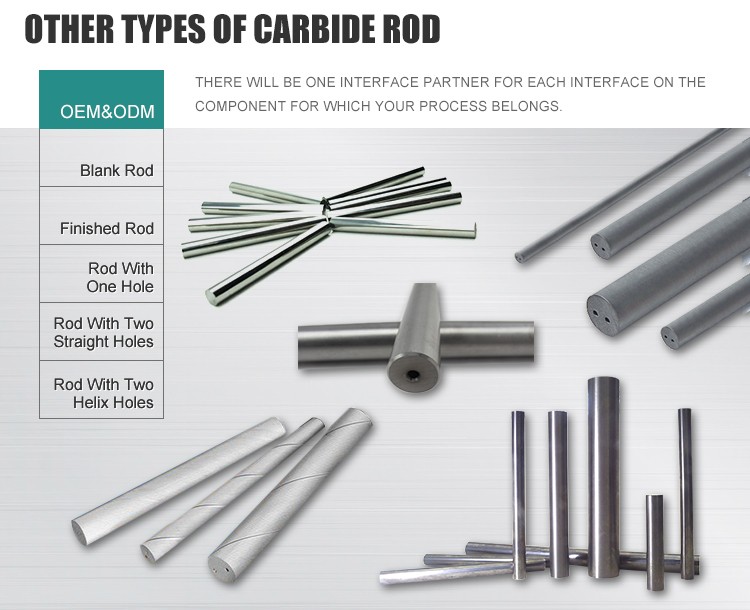

Changsha Jingxin carbide rods are available in many grades and can be used for different applications; complete specifications, accurate blank size (to reduce processing volume and improve production efficiency), mirror polishing, flush, chamfering, wire cutting, tip grinding, multiple steps and processing of various shaped parts, non-standard tools, etc.