| Availability: | |

|---|---|

| Quantity: | |

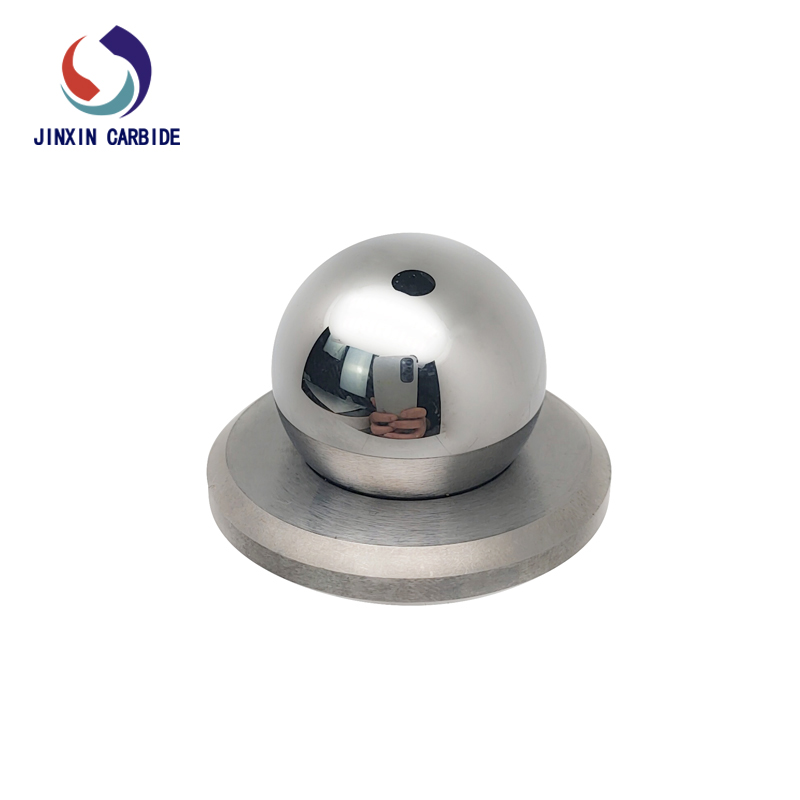

carbide valve seat

Jinxin

Product Description

Tungsten carbide valve seats for precision machining have been widely used in many fields, especially under harsh working conditions, due to their excellent properties such as high hardness, wear resistance, high temperature stability, oxidation resistance, corrosion resistance and high strength. It can not only ensure the sealing and stability of the valve, but also extend the service life of the valve and improve the overall performance of the system.

Tungsten Carbide Valve Features:

High hardness, density, and strength

Stable chemical performance

Good flexural strength and impact toughness

Excellent wear and corrosion resistance

Tungsten Carbide Valve Application:

Used with tungsten steel valve ball, carbide valve auxiliary, and valve sleeve.

Ideally suited for the high pressure, high temperature and corrosive environments of the oil and gas drilling industry.

Product Parameter

| Grade | YG6 | YG8 | YG6X | YL10.2 |

| Hardness HRC | 89.5 | 89.5 | 91 | 92 |

| Bending strength | 1800MPa | 1700MPa | 2100MPa | 4000MPa |

| Density | 14.95 | 14.75 | 14.95 | 14.5 |

| Grain size | 1.6um | 1.6um | 1.0um | 0.8um |

| Porosity | A04B00 | A04B00 | A02B00 | A02B02 |

Ball mills are widely used in metallurgy, mining, electric power, building materials, chemical industry and other fields, and are the most commonly used crushing equipment. Grinding media are balls or cylindrical objects that roll in the ball mill. The grinding media of ordinary ball mills are mainly metal balls and cylinders, while in the ceramic production industry, ceramic grinding media are mainly used, followed by natural flint and pebbles. The ceramic grinding media on the market in my country mainly include alumina, zirconium oxide, silicon carbide, silicon nitride and other series.